Bobst Bielefeld GmbH

Booth number: H4GM-E30

www.bobst.com

About us

We are one of the world’s leading suppliers of substrate processing, printing and converting equipment and services for the label, flexible packaging, folding carton and corrugated industries. Our vision is to shape the future of the packaging world based on four pillars: connectivity, digitalization, automation and sustainability.

Founded in 1890 by Joseph Bobst in Lausanne, Switzerland, BOBST has a presence in more than 50 countries, runs 21 production facilities in 12 countries and employs more than 6 400 people around the world. The firm recorded a consolidated turnover of CHF 1.891 billion for the year ended December 31, 2024.

Address

Hakenort 47

33609 Bielefeld

Germany

E-mail: sales.bobst-bielefeld@bobst.com

Phone: +49 521 30480

Internet: www.bobst.com

Plot No.82 Vill.Kasar Amboli Post, Ambadvet Taluka-Mulshi

412108 Pune

India

E-mail: nilesh.pinto@bobst.com

Phone: +91 20 39878000

Internet: www.bobst.com

Contact person:

Yogesh Koshti

Manager Sales

E-mail: yogesh.koshti@bobst.com

Phone: +91 98 19151050

Krupesh Kansara

Manager Sales

E-mail: krupesh.kansara@bobst.com

Phone: +91 96 24710149

Rakesh Bhat

Manager Sales

E-mail: RakeshKumar.Bhat@bobst.com

Phone: +91 93 13675791

Nilesh Pinto

E-mail: Nilesh.Pinto@bobst.com

Phone: +91 93 24569206

Products & Services

BOBST masters all the key technologies required to produce all type of labels efficiently - flexography, digital inkjet, embellishment and finishing. From 1 to 1 million labels, optimize your entire production floor by choosing and building the platform that best meets your customer requirements.

The modular and upgradable All-in-One hybrid solutions provide flexibility and agility to address a wide range of applications with a single equipment.

With the highest digital and analogue integration and automation, our digital and hybrid solutions are available in 340 mm and 510 mm print widths in a new design that has been optimized for full modularity, improved operation and servicing.

VISION CI

The VISION CI is designed to deliver the most efficient performance for all production lengths on a wide range of substrates. Fast to setup and change over, it features technical innovations and automation that ensure repeatable process consistency, minimum waste and easy manufacturing. It is ideal for converters looking to add a powerful and reliable production tool to their operation.

Smart press design for cost-effective production

Highly modular concept enables very fast installation and start-up

Automatically opening and closing bearings for plate cylinder equipped with a pre-load system for maximum stability. Deck design avoiding deflection and tilting

The joint action of the two component doctor blade chamber, the smart inking and easy cleaning systems increase press uptime

Dual technology nozzles in the tunnel ensure optimum drying performance

Operator viewing platform on catwalk for web monitoring of the print result and a convenient access to CI drum ensure higher machine productivity and availability

Automatic face-to-face winders

Wide range of standard options

Available as 8-color and 10-color press.

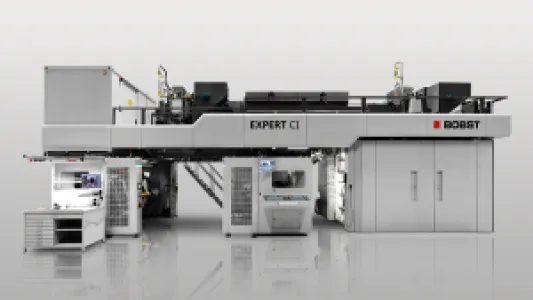

EXPERT CI

Advancing process consistency

The innovative features of the EXPERT CI platform succeed in maximizing CI flexo process consistency. It delivers stable and controlled printing results and exceptional productivity with both solvent and water-based inks. Its exclusive technical solutions make it a perfect fit for the requirements of the 7-color Extended Color Gamut printing process.

Exclusive innovations for unrivalled performance

Minimum waste of substrate and consumables at start-up and job changes with smartGPS or smartSET exclusive systems for registration and impression setting

smartFLO inking system and chamber doctor blade delivering predictable, stable and controlled printing results with all ink types

triLOCK bearing system with high torque mechanism replacing manual locking

Full Surface Matrix intercolor dryer preventing substrate stretching

oneECG for optimized results with 7-color ECG process

Hybrid, dual technology tunnel. Energy saving due to efficient drive system and ventilation

Fully automatic bi-directional reel splice at machine production speed. Winders' energy recovery solution

Compact footprint with face-to-face winders.

Exceptional printing flexibility

Select from 4 printing systems:

Solvent-based printing

Water based printing

E-beam printing

Extended Color Gamut printing (ECG)

smartGPS off-line fully automatic system for registration and impression setting or smartSET-press semi-automatic set-up system

Modular extendable configuration of the drying tunnel

Customizable for specific product requirements - downstream flexo units, gravure printing units and turning bars for reverse printing.

Connected and automated for maximum uptime

Accurate process automation for minimized waste, increased cost efficiency and easy manufacturing

Connectivity features to enable access to production data from remote services

IoT including Predictive Maintenance empowering the operator to change wear parts before they fail.

RS 5003

Qualitative, cost-effective and sustainable production

The solutions in the RS 5003 platform deliver superior performance on a variety of flexible materials, including the new eco-friendly packaging substrates for the efficient production of short, medium and long runs of food, beverages and non-food flexible packaging applications. Easy to operate and fast to make-ready and changeover, they feature BOBST unique solutions for sustainable operation with minimum waste for water-based or solvent-based ink printing applications.

Superior print quality and consistent performance

No compromise. High quality printing and speed combined at the same time. Printing on a wide range of materials including new eco-friendly substrates.

Easy web handling and very precise web tension control from the unwinder to the rewinder. No wrinkles even with critical/heat sensitive/stretchable substrates

Precise and uniform ink distribution system solutions to best fit application requirements and use of local ink varieties:

motorized inking roller (MPI)

idle inking roller (HSM)

Enhanced BOBST viscosity control system with ink cooling device for outstanding stability of the printing process.

BOBST supplies and integrates all required auxiliary equipment.

Advanced sustainability and cost savings

Reduced waste through short web path, register pre-setting and minimum volume of ink in circulation

Total Automatic Pre-register Setting (TAPS) for fast machine set-up and minimum waste independent of the press operator skills available as option

Integrated Registron® register control for very fast and precise register correction

Highly efficient Twin Flow dryers with double airflow and dedicated ventilation systems

Fully automatic bi-directional reel splice at machine production speed. Winders energy recovery solution

Lower Explosion Limit (LEL) system reducing emissions into the atmosphere available as option.

Automated and connected

Exclusive automation features ensuring process repeatability and required productivity

BOBST SPHERE Human Machine Interface, with common style and usability across all BOBST equipment

Connectivity features for full production and quality control:

Connectivity to enable remote access to production and process data

Fast troubleshooting process minimizing breakdowns

High level of security and protection for solving issues online without a technical intervention on site.

Advanced customer experience at Bobst Changzhou's facility

Print demonstrations or printing of customer jobs

Analysis of job production data such as solvent retention and quality control

Training classes in Chinese and in English by expert operators.

VISION K5 HS

High performance metallizing

BOBST is continually innovating and the VISION K5 HS (high speed) metallizer is no exception, the machine incorporates a Ø 700 mm coating drum providing the largest coating window in the industry and has been designed to handle a wide variety of different film types including heat sensitive, thin gauge and sustainable substrates with new features to improve metallizing performance on PE and low temperature Heat Sealable BOPP films.

Total flexibility

High speed metallizing

Designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates

Ideal for converters of PE

Incorporates the BOBST renowned winding mechanism.

Improved cooling

Largest coating drum in the industry at 700 mm

Increased cooling efficiency for PE & low SIT films

Largest coating window in the industry with improved collection efficiency

Less aluminium consumption and improved boat life.

High performance

100 mm full staggered boat arrangement

Improved coating uniformity at high speeds

Minimum roller contact

Designed for careful handling of heat sensitive substrates.

EXPERT K5

Automating metallizing

The next generation of the BOBST EXPERT K5 Metallizer is the first automated metallizer in the flexible packaging industry. It is optimized to handle sustainable substrates including BOPE, MDO PE, CPP and Paper) and low temperature Heat Sealable BOPP films.

Process expertise in-built

Higher quality metallization

In-built operator support

BOBST iMA software powered by AI which automates and controls deposition process

New operator console with controls all in one place

Automatically selects optimized setting for different processes

Remote support possible with BOBST iMA in conjunction with BOBST Connect.

Outstanding performance

Improved metallized roll quality due to increased automation

Increased output of up to 100 tonnes per annum

Ability to house increased roll diameters up to 1,270 mm

Largest coating window in the industry with improved collection efficiency of 16%

Largest diameter coating drum in the industry at 700 mm

Incorporates the BOBST renowned winding mechanism.

Lowest production costs in the market

Reduced production cycle increasing number of rolls per day

20% savings in production costs

Maximum machine uptime

Total Cost of Ownership reduced by 10-15%

oneBARRIER

Integrated solutions for recycle-ready high barrier packaging

Overcoming the technical complexities of developing and manufacturing sustainable high barrier flexible packaging that is recycle-ready is a major challenge, even more so since the market looks for new solutions with the right barrier performances to replace the multi-material non-recyclable packaging.

With oneBARRIER, BOBST has undertaken a design and testing project that is creating industrially viable recycle-ready mono-material ultra-high and high barrier duplex and triplex substrates for packaging designers as alternatives to non-recyclable metallized polyester film. Developed with leading industry partners, the family of BOBST oneBARRIER sustainable solutions to date includes PrimeCycle, comprising EVOH and topcoat-free transparent AlOx-based or opaque AluBond-based full PE mono-substrates, and FibreCycle, a mono-material high-barrier paper-based structure coated with functional layers that can be recycled in the existing paper stream.

The BOBST & Partners oneBARRIER solutions are the outcome of joint process and equipment development and testing. The advantages for converters are manyfold:

Integrated package solution: process-machine-output in one flow

Knowledge of both coating and vacuum metallizing equipment technology and processes from a single supplier

Different kinds of raw material specifications, coating, and adhesive chemicals

Guaranteed barrier properties of the full structures (pre-coat + metallization + post coat + eventually lamination)

The result is a fully reliable process to consistently produce top quality polyolefin-based or paper-based recycle-ready ultra-high or high barrier packaging, with faster time-to-market from day one.

The oneBARRIER equipment package comprises the EXPERT K5 vacuum metallizer and the oneBARRIER EXPERT COATER or the one BARRIER MASTER COATER coating lines, depending on the converter's productivity needs. oneBARRIER solutions web widths range from 1300 to 2900 mm.

EXPERT K5 vacuum metallizer

Perfectly accurate web handling on all paper and film types and thicknesses, including the new generation of sustainable substrates (BOPE, MDO PE, CPE) and low temperature heat sealable BOPP films

Handles AlOx deposition process for production of clear film and AluBond metallizing process for production of opaque film

High cooling capacity with largest diameter coating drum in the industry at 700 mm

Largest coating window in the industry with improved collection efficiency of 16%.

oneBARRIER COATER coating lines

Perfectly accurate web handling on all paper and film types and thicknesses, including the new generation of sustainable substrates (BOPE, MDO PE, CPE) and low temperature heat sealable BOPP films

Excellent coating profile consistency with water-based and solvent-based coatings

Single or multiple coating heads as option

Modular trolley-type configuration allowing for future changes of application technology

Hybrid dual technology dryer or full floatation dryer with option for additional tunnel sections.