INOMETA GmbH

Booth number: H4GM-D16

www.inometa.de

About us

INOMETA is part of the AVANCO Group, the leading company in the development, manufacture and distribution

of web guide, sensor and functional rollers, printing adapters, technical tubes, electric

heating rollers, functional surfaces and technical winding cores. The focus is on lightweight construction using aluminium

and carbon fibre composites and the associated increase in added value and productivity.

Independent experts regularly review our processes according to the strictest criteria.

This ensures the high quality of our products.

Address

Planckstraße 15

32052 Herford

Germany

E-mail: info@inmoeta.de

Phone: +49 5221 7770

Internet: www.inometa.de

Contact person:

Products & Services

INOMETA is a technological leader for the development, production, and finishing of technical lightweight design products made of aluminium and fiber composites such as CFRP and GFRP. We specialize in high-end, innovative lightweight solutions; as well as the development and production of functional surfaces. Our product portfolio ranges from technical pipes, roller tubes, winding cores, and web guide rollers to anilox rollers, air cylinder, adapters, and highly versatile functional coatings. With this product range, we are able to cover the entire spectrum of rotating elements for the film, paper, printing, packaging and converting industries.

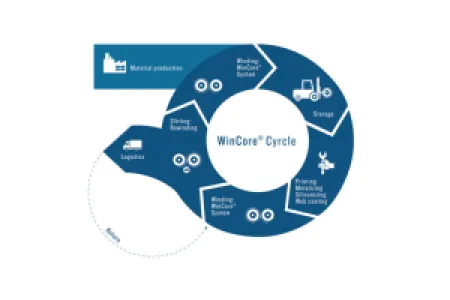

WinCore® Winding Cores

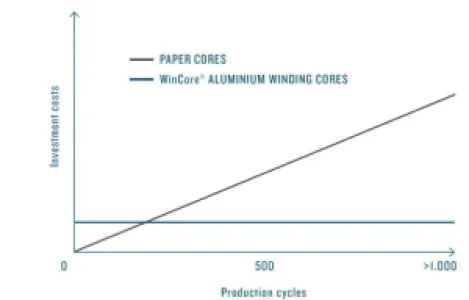

Our WinCore® aluminium winding cores offer a significant advantage over traditional cardboard cores. While cardboard cores are disposable and costly, WinCore® cores can be reused hundreds of times, leading to substantial long-term cost savings.

A single WinCore® core can replace up to 500 cardboard cores. Their durability makes them ideal for both in-house and standardized production processes.

With our aluminium winding cores from the Ecoline and Proline series, with winding support and cut-resistant surface, we offer you solutions that can be used over 1000 times in closed production cycles – for sustainable and economical production, as well as to increase efficiency and reduce material waste.

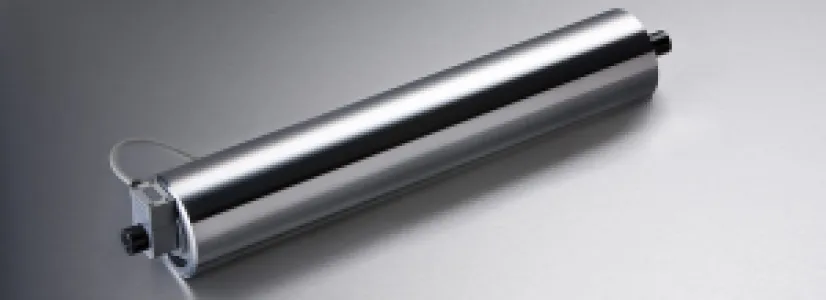

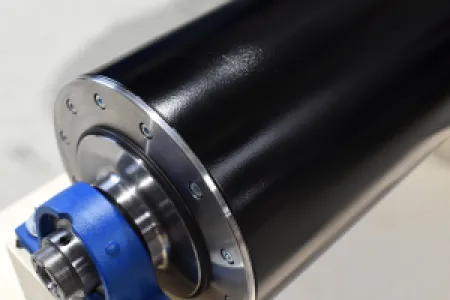

INOheat® heating roller

The innovative INOMETA INOheat® heating roller has been designed with the needs and requirements for coating and laminating films and other substrates in mind. We ensure a reliably constant and uniform surface temperature distribution, as this is the prerequisite for even material web tempering.

A fast start-up curve of the heating power and precise temperature distribution control on the roller surface are what makes the electric heating roller stand out from competing products. The maximum lasting operating temperature is 220°C.

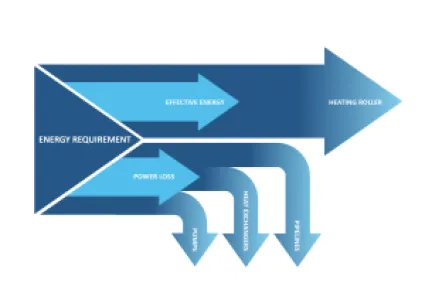

Owing to their electrical mode of operation, the heating rollers do not need any liquid media, the power and signals are transmitted via a flange-mounted slip ring contact. Heat losses outside the roller through the pipe system are thus now a thing of the past.

INOid® – high-performance data transmission

INOid®, our innovative app development, simplifies product information management for businesses of any size. This leads to increased efficiency, reliability, and provides access to valuable services.

QR codes and RFID tags for product-specific information

INOid® empowers our customers to make informed decisions. With complete information at their fingertips, they can optimize their processes to minimize downtimes, errors, and delays. Our intuitive and fast QR code and RFID tag scanning technology ensures easy and quick access to data. With a simple scan, network partners gain instant access to a wide range of essential documents, including measurement reports, delivery bills, and maintenance manuals. Additionally, they can access product and machine-specific services, maximizing the benefits of INOid®.

Universal solutions for customized processes

INOid®‘s strength lies in its manufacturer-agnostic design, making it a universal solution for managing rotating components. It seamlessly integrates into existing workflows and eliminates the need to juggle multiple platforms. For components that do not have built-in INOid® functionality, our platform provides an easy installation process. Our growing network of service partners ensures that our customers have access to specialized support for their specific production needs anytime, anywhere. With complete real-time information, potential problems are identified early, allowing proactive measures to be taken before costly downtime occurs.

All the advantages of INOid® at a glance – shape the future with INOMETA

Optimized document management

Instant and reliable access to relevant documents

Easy scanning of QR codes or RFID tags

Easy upgrade for products without a pre-installed INOid® app

Booking product and machine-specific services via the app

Growing network of service partners

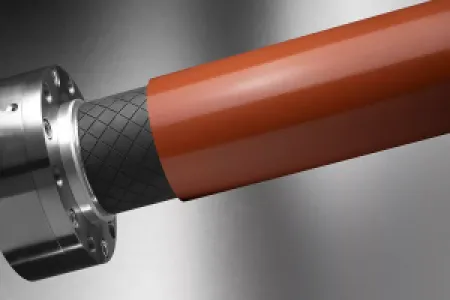

Aluminium & CFRP web guide rollers

INOMETA rollers stand for high quality and a sophisticated design

Our aluminum web guide rollers have been tried and tested for many years. Their sophisticated design which allows for a very smooth running, guarantees a high degree of productivity and technical security. We conduct our production using a modular system with pre-manufactured components. Through this, we are able to ensure competitiveness, consistent quality, reproducibility and short delivery times.

INOMETA’s web guide rollers are used in a wide range of demanding industries – wherever sensitive, functional, or high-quality webs need to be guided, coated, tempered, or finished in a reliable manner.

Sensor rollers

INOMETA sensor rollers with an integrated web tension measurement unit ensure a precise web tension determination and a smooth material transport.

Special properties:

Ready-to-install

Effective overload protection

Precise sensors

Proven roller technology

-thumb.webp)