NGA Plastic Technology Pvt. Ltd.

Booth number: H6M-C02

www.nga-solutions.in/

About us

NGA Plastic Technology was founded as an 80% subsidiary of the Austria-based NGA Group, with 20% owned by Techscience Services PVT LTD from Chennai, India. The company’s mission is to supply emerging markets with easy-to-use lab-scale testing, R&D lines and recycling solutions, based on proven COLLIN technology and manufactured in India under the brand “COLLIN Asia.”

The product line, EASY LINE, includes compact, table-top machines for polymer processing, training, research, and development—such as presses, extruders, compounders, roll mills, flat film lines, blown film lines, pressure filter tests and automatic band melt filter for recycling.

With India as a key growth market—especially for masterbatch, compounding, and film production—the company also serves Southeast Asia and Africa.

The NGA Group also includes COLLIN Lab & Pilot Solutions (Germany), BritAS Recycling-Anlagen (Germany), COMELT Collin Melt Solutions (Austria), NGA Plastic Technology Inc. (USA), and NGA Plastic Technology (Singapore).

Address

Unit 4&5, Block II, Sidco Electronic Complex, Thiru Vi Ka Industrial Estate, Guindy

600032 Chennai Tamil Nadu

India

E-mail: rajnissh@nga-solutions.in

Phone: +91 990 9742078

Internet: www.nga-solutions.in/

Contact person:

Rajnissh Soodd

Country Manager NGA Plastic Technology Private Limited

E-mail: rajnissh@nga-solutions.in

Phone: +91 990 9742078

EASY LINE extruder

The EASY LINE single-screw extruder is the standard unit for the continuous plastification of polymers. The extruders of the COLLIN EASY LINE series have an output of between 50 and 3000 g/h. They are the ideal tool for training and science as well as for research and for the testing of new materials in small batches. The design has a very small footprint and is therefore the ideal machine to build co-extrusion lines.

Applications:

Ideal tool for training and science as well as for re search for the testing of new materials in small batches

Perfect machine to build up co-extrusion lines

Advantages:

Table-top machine, ergonomic design

Very small footprint

High processing variability

Exact control and adjustment of all parameters

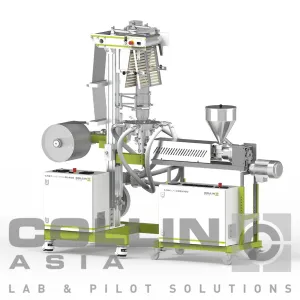

EASY LINE blown film line MAX

The EASY LINE blown film line is a line for the production of blown films from all commercially available polymers. The line consists of an E25 x 30D extruder or an E30 x 30 D extruder, a mono blown film head and a blown film unit (BL 400). A blown film head (possible diameters for blown film are 50, 60, 70, 80 mm gap 1.2 or 1.4 mm) with optimised melt flow and a cooling ring with adjustable gap guarantees an extremely thin and uniform blown film.

Applications:

Processing blown films from all common, non corrosive, commercially available polymers

Technical data:

2 Extruder sizes are possible: ø25x30D and ø30x30D

Blown film unit: U=3x400/230V; f=50Hz; P=2kW; I=3x16A

Web speed: 3-30 m/min

Roller width: 400 mm

Max. operation temperature of extruder and die: 300°C

Max. melt pressure: 300 bar

Advantages:

Very compact line

Thin blown film

Ergonomic design

Easy to handle

EASY LINE pressure filter test

Polymer melt is pressed with a defined volume through a melt filter and the pressure in front of the melt filter is monitored. Particles (contaminations, agglomerates in pigments, etc.) are caught in the filter and the pressure increases in front of the melt filter. The calculation of the pressure filter value (FT), according ISO 23900-5, starts at the end of the test by determining the initial pressure (P start) and the final pressure (P max) divided by the piment weight.

Main applications:

Testing of pigment or additive dispersion

Inspection of contamination in virgin and recycled polymers

Advantages:

Extremely reduced downtime

Reduction of the staff requirement

Extremely safe in operation

Manually operated

Melt valve for continuous measuring without stopping the extruder

Melt pump for constant melt flow-rate

Melt filter preheating

All design parameters and the evaluation correspond to the

ISO Standard 23900-5

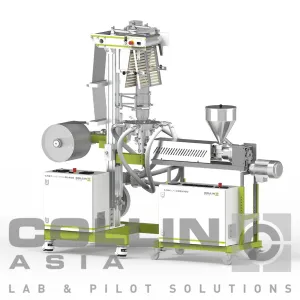

EASY LINE flat film line MAX

The EASY LINE MAX Flat Film Line CR 400 is a two chill roll unit with horizontal arrangement of the roller group that allows the simulation of all known processes of cast film.

Applications:

Casting of common, non corrosive, commercially available polymers.

Features:

2 Extruder sizes are possible: ø25x30D and ø30x30D

Slot Die type SD 350 with flex lip, adjustable die gap 0.3-1.5mm, vertical die arrangement, optional lip heating 3” pneumatic winding shaft in cantilever design

Roller width 400 mm

Technical data:

Web speed 3-30 m/min

Max. operation temperature of extruder and die: 300°C

Advantages:

Compact machine, ergonomic design

Easy operation

Moveable machinery, because on wheels

BritAS Asia EASY LINE ABMF automatic band melt filter

Efficient Melt Filtration for Plastic Waste

The new BritAS Asia EASY LINE ABMF-0300-05 is designed for the effective and efficient filtration of

contaminated plastic waste. A fresh filter mesh is automatically inserted with every filter change – ensuring

constant regranulate quality and minimal melt loss.

Customer Benefits:

Efficient removal of contaminants from plastic waste

Easy melt filtration – ideal for small throughputs with best regranulate quality

Proven BritAS technology in a simplified design

Low operating costs

Fully automatic operation

Technical Data:

Filter area: 300 cm²

Throughput: 100 – 500 kg/h

Materials: PE, PP, PS, ABS

Filtration fineness: 80 – 800 μm

Output values (LDPE): dependent on material and contamination level

Note: NOT compatible with other BritAS filters, no upgrade options available.