Lutz GmbH & Co. KG

Booth number: H4GM-D18

lutz-blades.com

About us

Precision and sharpness – for your success!

LUTZ BLADES is a tool manufacturer and that is how the blade is understood here: as an industrial tool that lasts and is sharp – and meets the customer’s expectations all around.

Precision is our philosophy

Whether “razor sharp” for the finest cuts or “extremely stable” for impact and pressure cuts: Precision has been the philosophy of our company for more than 100 years – in everything we think, produce and deliver to our customers. Precision guides us from the idea to the finished product to the optimal solution for every cutting task. This is the only way we can meet the demands that customers place on us. In every development and manufacturing step – blade by blade.

To achieve this, we are committed to high quality, precision and sharpness in our work. Together with our customers, we define all relevant parameters necessary to meet individual requirements – for more sharpness and tool life. In doing so, we always see ourselves as a partner to our customers and focus not only on current but also on future customer needs.

We want our customers to be successful, because their success is our success.

Address

Piepersberg 20

42653 Solingen

Germany

E-mail: info@lutz-blades.com

Phone: +49 212 5966-222

Internet: lutz-blades.com

Contact person:

Sales Management Maximilian Zarnekow

E-mail: maximilian.zarnekow@lutz-blades.com

Phone: +49 212 5966-204

The right high-performance blade for every film machine

In other words, film production is an absolutely high-performance process. And that means that high-performance blades are also required. LUTZ BLADES has been supplying leading film manufacturers with excellent blades for years.

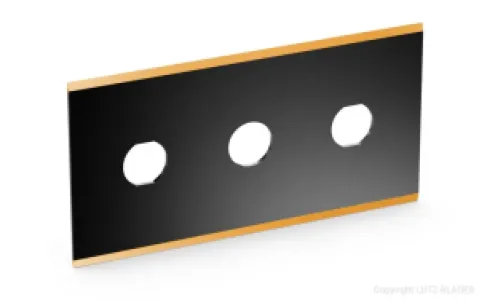

Whether as a slotted blade, a 3-hole blade, a round blade or an exact special shape according to customer drawings: We process different types of steel, carbides and ceramics and adjust our blades precisely to the specific cutting task of the user in terms of material, heat treatment and cutting geometry. Thanks to our special DLC or PTFE (Teflon®) hard material coatings, our blades have additional properties, such as high resistance or low frictional resistance.

We offer replacement blades for the following machine manufacturers, among others: Atlas®, Barmag®, Brückner®, Goebel®, Kampf®, Reifenhäuser®, SMI/Lenzing®, Starlinger® and Windmöller + Hölscher®.

Special cutting applications for the production of plastic granulate

Our pelletizing blades, also known as pelletizing blades, are used at the end of the manufacturing process to cut plastics into pellets. LUTZ BLADES has many years of experience in the manufacture of industrial blades for numerous industries and offers a wide range of different blade geometries. Of course, we also develop and produce customized special blades.

Only high-quality materials are used for the pelletizing blades from LUTZ Blades: They are made of carbon steel or bimetal with a particularly hard and wear-resistant alloy on the cutting edge.

Cutting applications for potato processing and chip production

Cutting processes in the potato processing industry place the highest demands on the efficiency and quality of blades - regardless of whether they are used for peeling or cutting potatoes into chips, fries or other products. That is why LUTZ BLADES manufactures a wide range of replacement blades and machine knives in this area and has been working successfully with leading potato processing companies worldwide for many years.

Excellent potato blades and potato knives increase the efficiency of potato processing and the quality of the product. LUTZ BLADES has been the global market leader in this field for many years. Our potato knives and blades are used for processing raw potatoes, which are cut into chips and fries.

They are available in numerous dimensions and are compatible with common machine manufacturers and types such as Urschel®, Stumabo®, Incalfer® and others.

Reliable cutting applications for meat production

Cutting processes in the meat industry place the highest demands on the efficiency and quality of blades - regardless of whether they are used for slicing, derinding, skinning, degreasing or cutting meat products. This is why LUTZ BLADES manufactures a wide range of replacement blades and machine knives in this area and has been working successfully with leading meat processing companies worldwide for many years.

With excellent derinding blades, skinning blades and creel knives, you not only increase the efficiency of your meat processing operations, but also the quality of the meat. LUTZ BLADES has been the global market leader in this field for many years. Our derinding and skinning knives are used in the processing of beef, pork and lamb.

They are available in numerous dimensions and are compatible with common machine manufacturers and types such as Grasseli®, Maja®, Marel®, Weber®, Cretel®, Steen®, Nock®, Townsend® and others.

Blades for medical and laboratory technology

Whether medical blades for histology, for pathology or for the pharmaceutical industry: at LUTZ BLADES you will find a wide range of blades for medicine and laboratory technology.

Our blades are mainly used in the field of skin transplants, laparoscopic procedures and in the manufacture of medical products. In these areas of application, it goes without saying that the blades are subject to the strictest specifications.

Because we know exactly what specifications our customers in the medical sector have to follow, we can also provide them with optimum support in the development of a blade. Whether blades for surgical laparoscopy, disposable blades for histology, microtome blades or blades for dermatome knives: we guarantee our customers that we focus on the end result and customer satisfaction when developing new blades.