MAAG Germany GmbH

Booth number: H6-B2

www.maag.com

About us

The MAAG Group is a broadly diversified global solutions provider with integrated and customizable systems in process technology for the polymer, chemical and petrochemical. Its Pump & Filtration Systems, Pelletizing & Pulverizing Systems, Recycling Systems and Measurement & Control Systems divisions consolidate the many years of experience and in-depth know-how of the AMN, AUTOMATIK, ETTLINGER, GALA, MAAG, REDUCTION, SCHEER, SIKORA, WITTE and XANTEC product brands. The MAAG Group currently employs over 1,900 people at production sites in Switzerland, Germany, France, Italy, the USA, and China. Additional sales and service centers in Brazil, India, Japan, Korea, Malaysia, Mexico, Poland, Thailand, Turkey and United Arab Emirates, ensure close attention to customers’ needs. For more information visit www.maag.com.

The MAAG Group is a business unit of Pumps & Process Solutions, a segment of the Dover Corporation.

Address

Ostring 19

63762 Grossostheim

Germany

E-mail: info@maag.com

Phone: +49 6026 5030

Internet: www.maag.com

Plot no 118, Manjusar GIDC Vadodara-Savli Road

391775 Vadodara, Gujarat

India

E-mail: MaagIndia@maag.com

Phone: +91 960 1752864

Internet: www.maag.com

Contact person:

Hassan Maftun

Sales Director MEA & India

E-mail: hassan.maftun@maag.com

Phone: +49 172 7384281

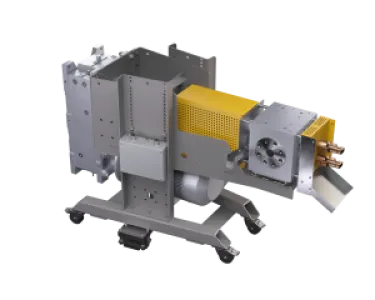

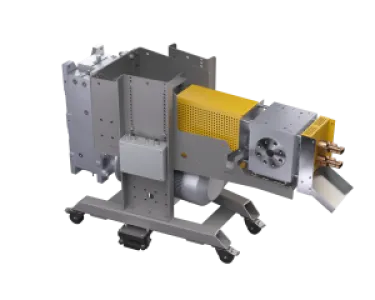

World first from MAAG Group: First gear pump specifically designed for pumping hard PVC

The MAAG Group, a global leader in the development of conveying and processing systems for the plastics industry, introduced a groundbreaking innovation after more than four years of intensive research and development: the first gear pump specifically designed for the continuous conveying of rigid PVC (polyvinyl chloride). The extrex⁶ EC opens a completely new chapter in PVC extrusion technology.

Rigid PVC is considered a particularly challenging conveying medium due to its thermal sensitivity and tendency to decompose. Conventional gear pumps often reach their limits when it comes to these requirements – deposits, material combustion, and process instabilities have been virtually unavoidable until now. The extrex⁶ EC was therefore developed specifically for this challenge: its gap-free design without dead spaces effectively prevents material from sticking and remaining in the pump. This significantly reduces the thermal load on the PVC – and thus also the risk of decomposition.

Technological highlights of the extrex⁶ EC:

· Gap-free design without dead zones: The innovative design eliminates dead spaces and thus potential extended dwell times of the material in the pump. This prevents thermal decomposition and ensures a stable, clean process.

· Up to 50% increase in extruder efficiency: The uniform, pressure-stable delivery significantly reduces the load on the extruder. Depending on the application, either the material throughput can be significantly increased or, at constant throughput, energy savings of up to 50% can be achieved in the extruder.

· Reduction of the process temperature by up to 10°C: The special design of the pump enables optimized temperature control in the melting process. This reduces the thermal stress on the material and makes the use of expensive stabilizers partially unnecessary – a considerable economic advantage.

The extrex⁶ EC thus offers a reliable and economically attractive solution for conveying rigid PVC – and sets new standards in terms of process reliability, product quality, and resource efficiency. With this new development, the MAAG Group once again reinforces its innovative leadership in plastics processing and makes a significant contribution to the sustainable optimization of extrusion processes.

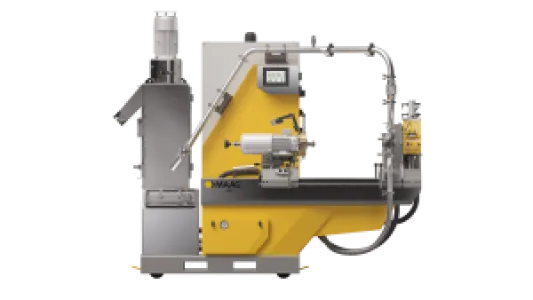

Start-up screen changer for sensitive polymers: compact, efficient, powerful

MAAG Group presents a new continuous screen changer design that enables higher throughput or energy efficiency by up to 50% while optimizing material usage: the CSC-230R-DV with integrated DV position.

This system is specifically engineered for processing copolymers such as EVA, ABS, or SAN, which may cause deposits, wear, and elevated energy consumption in conventional long melt flow systems. The goal is to process sensitive polymers under stable conditions with maximum efficiency.

Sensitive Materials Require Special Handling

The processing of copolymers requires precise temperature control and minimized residence time on the production line. Existing market solutions often rely on multiple melt adapters and additional startup components, such as startup-valves, which extend the flow channel or offer only small round or oval filtration areas. This requires higher energy consumption and can leads to reduced polymer quality, and limited economic viability. Many systems also require frequent screen changes and longer startup times, resulting in downtime and production waste.

For applications involving sensitive polymers like EVA, ABS, or SAN—as well as other shear- and temperature-sensitive materials—precise and consistent melt flow management is essential to avoid quality degradation and unnecessary material loss.

Compact Design for Stable Processes and High Efficiency

MAAG’s CSC-230R-DV features a compact, curved screen design with an integrated DV position. This configuration shortens the melt path, reduces dead volume, and minimizes thermal stress. Depending on the setup, it can deliver up to 50% more throughput or a significant reduction in energy consumption. The startup process is accelerated, startup waste can be reduced by approximately 20%, and production begins with clean screens for maximum service life.

The system stands out for its easy cleaning, user-friendly operation, and minimal footprint. Combined with high filtration performance, it ensures stable operation even with demanding materials. The CSC-R-DV series is suitable for virgin materials, extrusion processes, and applications involving sensitive polymers where thermal protection and energy efficiency are key priorities.

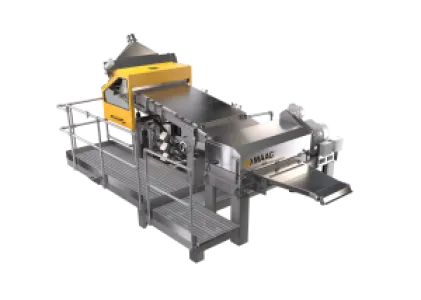

PEARLO CS from MAAG: Compact power for underwater pelletizing – efficient, flexible, user-friendly

MAAG Group presents its latest innovation in underwater pelletizing: the PEARLO Compact System (CS). With this compact system solution, MAAG Group expands its pelletizing portfolio and offers customers a modern, efficient, and user-friendly alternative to the outgoing LPU and EFLEX models. Designed for pelletizing rates between 50 and 500 kg/h, the PEARLO CS stands out for its small footprint and ease of operation.

A Versatile Compact System

The name “PEARLO” has long been synonymous with quality and process reliability, firmly established across a wide range of applications. With the addition of “CS” – Compact System – MAAG introduces a new solution for low-throughput underwater pelletizing that excels not only technologically but also in terms of space efficiency and operator comfort.

The PEARLO CS is a fully integrated system that includes all necessary components for efficient pelletizing. Its structured layout and compact design make it ideal for production environments with limited space or for operators seeking fast commissioning without complex system integration.

Proven MAAG Technology in a New Format

The PEARLO CS builds on MAAG’s well-established and field-proven technology. The system incorporates core components from the PEARLO series, including the tangential cutting chamber and optimized cutting tools. The overall system has been thoroughly redesigned and modernized to meet today’s production demands.

Another key advantage is its structured, maintenance-friendly design. Clear separation of functional areas ensures quick access to all maintenance-relevant components, minimizing downtime. MAAG continues its commitment to developing customer-oriented solutions that simplify daily operations.

Tailored for Small to Medium Throughput Ranges

With a throughput range of 50 to 500 kg/h and available in two sizes, the PEARLO CS targets production scales where flexibility and efficiency are equally critical. Many operators face the challenge of processing diverse materials under varying conditions—while maintaining high quality and low operating costs.

This is where MAAG’s PEARLO CS excels: the system allows for rapid product changes, handles a wide range of materials, and delivers exceptional process stability for maximum reproducibility. The result: consistent pellet quality, low scrap rates, and maximum flexibility.

A Successor with Real Improvements

The PEARLO CS supersedes the proven LPU and EFLEX models—two systems that have long been established in the market. However, the new system brings significant enhancements, including a reduced footprint and improved configurability.

Debut at the K-2025

The PEARLO CS will make its official debut at the K-2025 in Düsseldorf in October 2025. MAAG will present the new system and offer visitors the opportunity to experience the benefits of this compact solution firsthand.

With the PEARLO CS, MAAG demonstrates that compact design, advanced technology, and user-friendly operation are not mutually exclusive—but rather a powerful combination tailored to the needs of modern plastics processing.

Conclusion

With the PEARLO CS (Compact System), MAAG introduces a product defined by its compactness and ease of use. It offers a well-thought-out system specifically designed to meet the needs of small and mid-sized production environments.

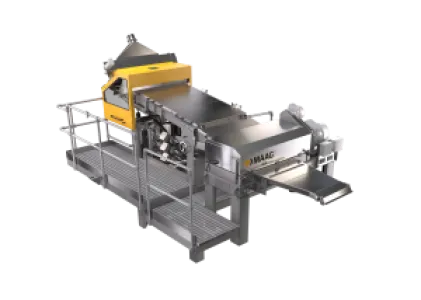

Maximum Process Stability and Pellet Quality for Next-Generation Production

New Features for Greater Efficiency and Quality

For decades, Maag has set benchmarks in underwater pelletizing. With the new M²-USG generation, the company now introduces a system that delivers enhanced process stability, increased throughput, and improved pellet quality—thanks to design upgrades and advanced sensor integration.

Focus on Reliability and Product Quality

This new development targets maximum availability (>99% OEE) and stable processes. Reduced downtime and scrap lower production costs and boost profitability. At the heart of the system is the new M²-USG cutting head, which simplifies operation and maintenance while minimizing operator errors. Maintenance is largely tool-free, and cleaning times are significantly reduced.

From Polymer Melt to Perfect Pellets

Maag systems produce uniform, cylindrical pellets with minimal fines. The melt is pushed through a die plate, cooled, and automatically guided into the pelletizer. Precise process parameters are crucial—incorrect settings can cause strand sticking and shutdowns. The M²-USG mitigates these risks through detailed optimizations, ensuring sustainable operation.

Mastering the Critical Startup Phase

During startup, polymer strands are automatically directed to the guide system. A newly developed scraper combines speed with gentle handling: strands are cut sequentially at the die plate and fed into the guide system with a time delay. This significantly reduces the risk of sticking, clogging, or startup waste, enabling faster and more stable process initiation.

Seamless Transition for Enhanced Stability

An optimized water film on the startup table prevents turbulence and strand adhesion. Additionally, transport water is injected immediately after cutting—avoiding blockages in the cutting head, even at high temperatures and with demanding polymers like polycarbonate. The system runs more smoothly and stably, increasing throughput and availability.

Larger Cutting Rotor for Higher Performance

The new cutting head is compact, optimized in design and comes with an improved sound-insulation. The rotor diameter has increased from 162.5 mm to 200 mm, with the number of blades upgraded from 30 to 36. Customers benefit from higher throughput and 20% longer service life. A stable cutting gap ensures consistent pellet quality while reducing maintenance and spare part costs.

High Capacity in a Compact Design

The M²-USG is available in widths of 600, 900, and 1200 mm. At 600 mm, it achieves up to 13’000 kg/h (PET), and up to 24’000 kg/h at 1200 mm—significantly more than previous models. This allows for smaller machine sizes, reducing investment costs and footprint.

Integrated Sensors for Maximum Efficiency

Sensors monitor vibrations, temperatures, flow rates, and pressures to ensure optimal cutting gap. Deviations are reported immediately, even remotely, helping to prevent scrap. A camera monitors strand flow, and compressed air is tracked. Additionally, energy-efficient reluctance motors contribute to further savings.

Conclusion

The new M²-USG leads the field with technical innovations, improved stability, and superior pellet quality. The M²-USG reduces operating costs, increases throughput and efficiency, and offers state-of-the-art sensor technology for maximum process reliability. A clear advancement in underwater pelletizing.

In short: The M²-USG proves that even a well-established pelletizing system can still be optimized.

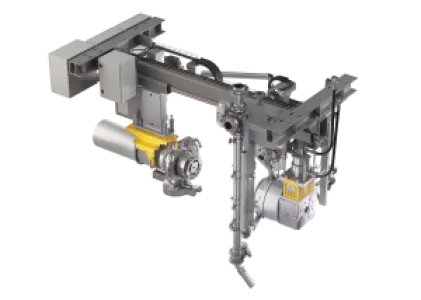

Newly developed double-stage melt filtration increases efficiency and recyclate quality

The combination of two high-performance melt filters offers operators the ability to continuously process even heavily contaminated plastic melts at high throughputs with fine filtration. The goal is to elevate the quality of recyclates to a level comparable to virgin material—while simultaneously optimizing plant efficiency.

Limitations of Melt Filtration in Recycling

Post-consumer recycling streams (PCR) from films, bottles, pipes, or from the automotive and construction industries are often contaminated with various material types and stubborn impurities. In addition to paper, wood, or metals, gels, rubber, and other highly viscous components pose particular challenges. Conventional filtration solutions quickly reach their limits when high viscosity, high throughput, and fine filtration are combined. Frequent filter changes, high labor requirements, and pressure fluctuations lead to increased production costs, waste, and downcycling.

Another barrier to high-quality recyclates is the limited service life of filters. Many systems operate under constant pressure for only a few days or weeks before a filter change is required. At low throughput rates, existing solutions are often uneconomical, and the processing of certain input streams is restricted.

Dual Filtration for Consistent Quality and High Cost-Efficiency

MAAG’s new dual-stage melt filtration system combines the disc filter (BRF) with the rotating drum filter (ERF), both of which clean continuously and provide a large open screen area at all times. In the first stage, the BRF removes coarse and medium-sized particles from the melt stream. The ERF, as the second stage, handles fine filtration. This division reduces the load on the second filter stage, resulting in significantly longer service life.

The system enables continuous operation over months without screen changes, maintaining constant pressure and minimal melt loss: approximately 0.5% with the BRF and around 0.3% with the ERF. It is the only system on the market where both stages can be individually adjusted via a single control unit to match the contamination level of the melt, ensuring optimal quality and throughput with minimal melt loss. Depending on the configuration, throughput can reach up to 10 tons per hour. A robust recycling pump ensures a consistent melt flow and expands the process window.

The dual-stage filtration system is suitable for a wide range of applications, including LDPE film recycling, HDPE bottles and pipes, PP from the automotive sector, PVC, and polystyrene from the construction industry. Operators benefit from higher recyclate quality, a stable process, and low operating costs.