COLLIN Lab & Pilot Solutions GmbH

Booth number: H6-B1

www.collin-solutions.com/

About us

Based in the Bavarian city of Maitenbeth, COLLIN develops laboratory, pilot and production lines in the modular system for the thermoplastics processing industry, universities as well as research institutes.

As part of the product lines LAB LINE, TEACH LINE, PILOT LINE, MEDICAL LINE, POLYTEST LINE, FOOD FEED LINE as well as SERVICE LINE, COLLIN develops individual solutions – platen presses, roll mills, calenders, extruders, compounders, mono- or co-extrusion lines, pressure filter tests, rheometers or optical inspection systems.

COLLIN solutions are used for developing and producing plastic products, material investigations and test series as well as pilot tests which allow to scale up to production scale measures.

Material manufacturers, compounders, film producers, companies in the field of medical technology, pharmacy and industry, universities, laboratories and scientific institutions count on COLLIN.

Address

Gewerbestr. 11

83558 Maitenbeth

Germany

E-mail: info@collin-solutions.com

Phone: +49 8076 2740-0

Internet: www.collin-solutions.com/

Contact person:

Products & Services

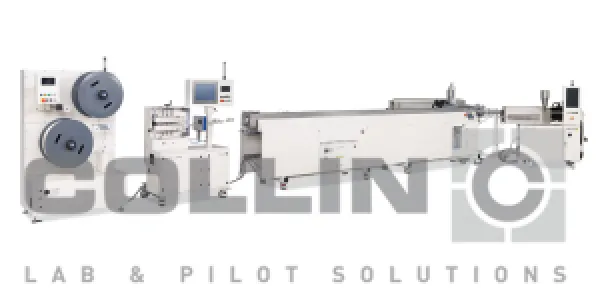

COLLIN PILOT LINE module line

Module lines are used in the packaging sector for the production of multi-polymer compounds, e. g. with carrier materials. The system allows the integration of different modules such as flat film, blown film and calendering unit as well as miscellaneous additional equipment, e. g. Corona pre-treatment or additional unwinders.

Custom-made solutions can be delivered for the following applications:

Flat film extrusion

Blown film extrusion

Smoothing – Embossing

Extrusion coating

Laminating

Take-off speed up to 200 m/min

Roll position mutually adjustable in x and y direction

Good accessibility

COLLIN LAB LINE press S

Press Type S particularly convinces with its quiet hydraulic aggregate, which does not run constantly. Moreover, no oil cooler is needed, resulting in a lower consumption of cooling water. Combined with an optional chiller, which is adapted to the press, a cooling water consumption can almost completely be avoided.

An additional advantage is the pneumatically, vertically movable door. Optically, the Press Type S impresses with its futuristic, reduced design.

High pressure accuracy +/- 0.5 bar

Very high temperature accuracy across the plate surface

High-precision regulation of the temperature and pressure ramps

Reduced energy consumption of the motor

Can be used within a temperature range from 20 to 300°C, optionally up to 450°C

User-friendly via touch-screen control

Type SV presses are equipped with a vacuum chamber

Test standard: standard practice for compression molding thermoplastic materials into test specimens, plaques, or sheets

Including the extended cooling ramp up to 45°C

Optional: Upgrade to fluoropolymer processing

COLLIN POLYTEST LINE pressure filter test

COLLIN pressure filter tests can determine the difference in quality of a polymer caused by agglomerates, insufficientlydispersed fillers resp. impurities. For example, they can be used in the field of production development for optimising colour masterbatches, for quality control or output and input control of masterbatches, compounds or polymers. The pressure filter tests can also be combined with numerous extruders or compounders.

A filter cassette in pre-heating position allows for a quick, clean and manual filter change without extruder stop. During the filter change, the melt is deflected via a bypass valve in front of the filter.

Easy and safe handling

Improved reproducibility by double-chamber hopper

Little idel times during screen change by cassette system

Filter change without extruder stop

Saving of working time due to optionally available double-chamber hopper

Applications:

Product development – optimizing colour masterbatches

Quality monitoring and control

Incoming inspection and output control of masterbatches, compounds or polymers

COLLIN MEDICAL LINE tube line

COLLIN tube lines are used for the production of multi-lumen resp. plastic tubes for medical applications, also multi-layer.

The spectrum of diameters ranges from thinner than a human hair (<100 µm) up to approx. 5 mm. By means of coextrusion, the properties of the tubes, with a design of up to 5 layers, are adapted to the requirements of the field of applications.

The inner geometry of COLLIN MEDICAL LINE tubes ranges from simple mono-lumen up to multi-lumen tubes, which contain up to seven channels, which are separated from each other. It is clear that all geometric parameters are extremely, narrowly tolerated. This geometric variety is multiplied by using different plastics.

Furthermore, polymer materials can be combined with metallic supporting bodies with different, geometric characteristics.

Advantages:

Up to 5 layers

Up to 7 separate channels

Enormous variability in production

Continuous production, compliance with all tolerance requirements

Lines, which can produce around the clock

Highly tempered stainless steel (316L) for all product-touching parts

Standard-compliant surfaces

COLLIN PILOT LINE flat film line

Flat film lines with two rolls are particularly used for the production of films.

Flat film lines in the pilot sector are especially designed for the customer. Depending on the customer requirement, different designs of roll groups can be offered.

Take-off speed standard up to 100 m/min, as option up to 200 m/min

Roll position adjustable in x and z direction to one another

Horizontal as chill roll (vertical die position)

Diverse accessories, for example camera inspection etc.

Upscaling to production lines